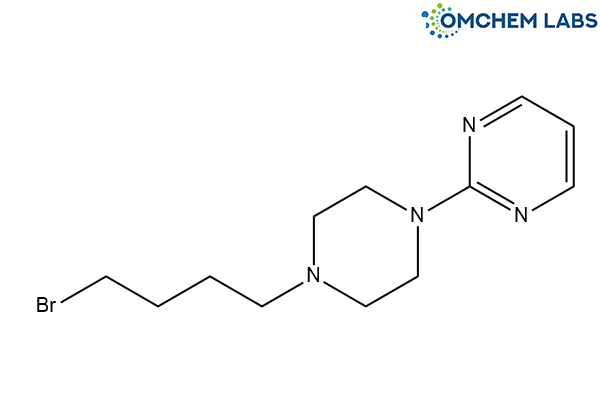

2-(4-(4-Bromobutyl)Piperazin-1-Yl)Pyrimidine

| Catalogue No |

BUSP-OCL-018 |

| CAS NO |

87789-48-8 |

| Molecular Formula | C12H19BrN4 |

| Molecular weight | 299.21 |

| Inquiry Status | In Stock |

| Synonyms | 2-(4-(4-BROMOBUTYL)PIPERAZIN-1-YL)PYRIMIDINE |

Detailed Overview of this Impurity: Discover more about Impurity Standard & Analysis

Impurity Profiling of 2-(4-(4-Bromobutyl)Piperazin-1-Yl)Pyrimidine: Scientific Considerations in Identification and Control

Introduction

Impurity profiling represents a fundamental component of pharmaceutical research and quality assurance. The presence of impurities in active pharmaceutical ingredients (APIs) can influence product stability, safety, and therapeutic performance. Therefore, comprehensive evaluation of impurities associated with compounds such as 2-(4-(4-Bromobutyl)Piperazin-1-Yl)Pyrimidine is essential throughout the development lifecycle. Impurities may originate from synthetic processes, raw materials, or degradation pathways, and their systematic identification forms the basis of regulatory compliance and patient safety. A well-designed impurity profiling strategy integrates chemical understanding, analytical science, and regulatory expectations to ensure consistent product quality.

Formation of Impurities During API Synthesis

Impurities related to 2-(4-(4-Bromobutyl)Piperazin-1-Yl)Pyrimidine may arise at various stages of synthesis, beginning with the selection of starting materials and extending through final isolation. Incomplete reactions, competing side reactions, and interactions between intermediates can lead to structurally related by-products. Residual reagents, catalysts, and solvents may also contribute to the impurity profile if not adequately controlled.

Additionally, changes in reaction conditions such as temperature, solvent system, reaction time, or pH can alter reaction pathways and promote the formation of unintended species. Post-synthesis handling and storage conditions may further introduce degradation impurities through exposure to moisture, oxygen, or light. Understanding these potential sources enables the development of preventive strategies and supports robust process design.

Analytical Data Interpretation Techniques

Reliable impurity profiling of 2-(4-(4-Bromobutyl)Piperazin-1-Yl)Pyrimidine depends on the effective application and interpretation of modern analytical techniques. Chromatographic methods, including high-performance liquid chromatography and gas chromatography, are commonly employed to separate impurities from the main compound. Coupling these techniques with spectroscopic tools such as mass spectrometry and nuclear magnetic resonance enhances structural insight and identification capability.

Interpretation of analytical data involves assessing chromatographic behavior, spectral patterns, and relative signal intensities to distinguish impurities from the parent compound. Comparative analysis across batches helps establish process consistency and detect emerging impurity trends. Together, these approaches provide a comprehensive understanding of impurity profiles without reliance on compound-specific numerical values.

Method Validation for Impurity Detection

Analytical methods used for detecting impurities in 2-(4-(4-Bromobutyl)Piperazin-1-Yl)Pyrimidine must be demonstrated to be suitable for their intended purpose. Method validation ensures that procedures are reliable, reproducible, and capable of detecting impurities at appropriate sensitivity levels. Key validation characteristics include specificity, precision, accuracy, linearity, and robustness.

Validation activities confirm that the method consistently differentiates the target compound from related substances and potential degradants. This process supports regulatory acceptance and provides confidence that impurity results accurately reflect the true quality of the material being tested.

Purification Strategies for Reducing Impurities

Purification plays a central role in minimizing impurity levels associated with 2-(4-(4-Bromobutyl)Piperazin-1-Yl)Pyrimidine. Selection of purification techniques depends on the physicochemical properties of both the target compound and its impurities. Common approaches include crystallization, solvent extraction, distillation, and chromatographic separation.

Optimization of purification conditions aims to maximize removal of undesired species while preserving product yield and integrity. Integration of purification steps into the overall manufacturing process contributes to consistent quality and reduces the likelihood of impurity carryover into final material.

Isolation and Characterization of Impurities

When impurities exceed identification thresholds or require further evaluation, isolation and characterization become necessary. Preparative chromatographic techniques are typically employed to obtain sufficient quantities of impurities for study. Structural characterization is performed using spectroscopic tools such as NMR, MS, and IR, providing insights into molecular architecture and functional groups.

Understanding impurity structures supports toxicological assessment, establishment of acceptance criteria, and development of reference standards. This knowledge strengthens regulatory documentation and enhances long-term control strategies.

Conclusion

Impurity profiling of 2-(4-(4-Bromobutyl)Piperazin-1-Yl)Pyrimidine is a multifaceted scientific process that combines synthetic chemistry, analytical evaluation, method validation, purification, and structural characterization. A systematic and proactive approach to impurity management ensures compliance with regulatory expectations while safeguarding product quality and patient safety. By implementing robust impurity control strategies, pharmaceutical manufacturers can achieve consistent and reliable production of high-quality materials.