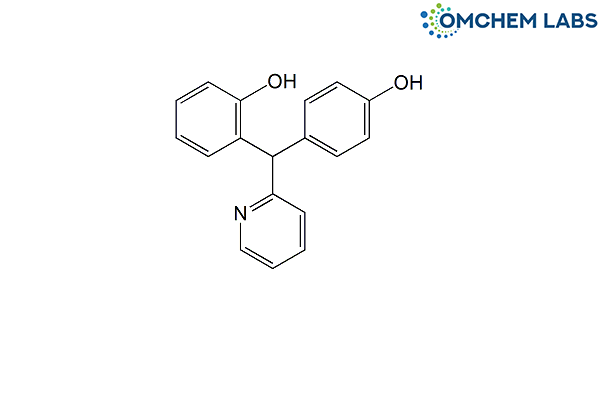

Bisacodyl Impurity B

| Catalogue No |

BISA-OCL-003 |

| CAS NO |

16985-05-0 |

| Molecular Formula | C18H15NO2 |

| Molecular weight | 277.32 |

| Inquiry Status | In Stock |

| Synonyms | 2-[(RS)-(4-Hydroxyphenyl)(pyridin-2-yl)methyl]phenol |

Detailed Overview of this Impurity: Discover more about Impurity Standard & Analysis

Impurity Profiling of Bisacodyl Impurity B: A Comprehensive Overview

Introduction

The profiling of impurities in pharmaceutical active ingredients remains a cornerstone of drug development and quality assurance. Bisacodyl Impurity B, like other process- and degradation-related impurities, demands thorough investigation to ensure the safety, efficacy, and regulatory compliance of the final drug substance. Impurity profiling encompasses the identification, quantification, and control of both known and unknown impurities throughout the product lifecycle. This process is critical not only for meeting pharmacopeial standards but also for understanding the chemical stability and synthesis pathways that influence impurity formation.

Formation of Impurities During API Synthesis

Impurities related to Bisacodyl Impurity B generally arise from multiple facets of the synthetic process. During chemical reactions, incomplete conversions, side reactions, or reagent decomposition can generate unwanted by-products. Factors such as reaction temperature, solvent selection, pH, and catalyst presence directly influence the type and concentration of impurities formed. Moreover, impurities may also result from the degradation of intermediates or the active pharmaceutical ingredient itself during downstream processing or storage. Awareness of these origins is essential for designing robust synthesis and purification protocols.

Analytical Data Interpretation Techniques

The identification and monitoring of impurities in Bisacodyl Impurity B rely heavily on sophisticated analytical methodologies. Techniques such as high-performance liquid chromatography (HPLC) and gas chromatography (GC) are routinely used to separate impurity mixtures and quantify individual components. Coupling chromatographic separation with mass spectrometry (MS) and nuclear magnetic resonance (NMR) spectroscopy further facilitates the structural elucidation of unknown impurities. Proper interpretation of chromatograms, spectral data, and mass fragmentation patterns is vital for distinguishing impurities from the parent compound and ensuring accurate impurity profiling.

Method Validation for Impurity Detection

The reliability of impurity data depends on the rigorous validation of analytical methods. Validation ensures that the techniques used to detect Bisacodyl Impurity B impurities are precise, accurate, specific, and sensitive across relevant concentration ranges. Parameters such as limit of detection (LOD), limit of quantitation (LOQ), linearity, and robustness must be established following international guidelines. Method validation not only assures the credibility of impurity assessment but also supports regulatory submissions and ongoing quality control.

Purification Strategies for Reducing Impurities

Effective purification is integral to minimizing impurities in Bisacodyl Impurity B manufacturing. Techniques including crystallization, solvent extraction, distillation, and chromatographic purification are selected based on impurity characteristics and physicochemical properties of the target compound. Optimization of these purification steps reduces impurity load and enhances overall product purity and yield. The selection of appropriate purification methods is guided by impurity profiles and the need to meet strict regulatory impurity limits.

Isolation and Characterization of Impurities

When impurities exceed regulatory thresholds or remain unidentified, isolation and detailed characterization become essential. Preparative chromatography enables the collection of impurity fractions for further study. Subsequent characterization employs spectroscopic methods such as NMR, MS, and infrared spectroscopy to define impurity structures. This information aids toxicological evaluation and supports the development of impurity reference standards. Comprehensive characterization ensures a thorough understanding of impurity origins and their potential impact on product quality.

Conclusion

Impurity profiling of Bisacodyl Impurity B represents a multifaceted scientific endeavor encompassing synthesis understanding, advanced analytical techniques, stringent method validation, and strategic purification and characterization. This process is paramount for ensuring product safety, efficacy, and regulatory compliance. A robust impurity control strategy, adaptable to evolving process conditions and regulatory expectations, is indispensable for maintaining high-quality pharmaceutical products throughout their lifecycle.