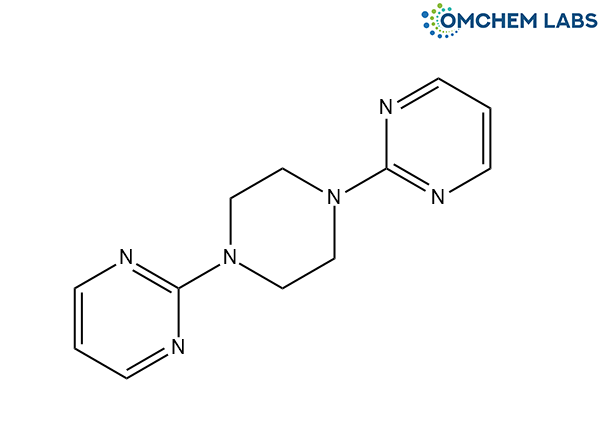

Buspirone Impurity G

| Catalogue No |

BUSP-OCL-007 |

| CAS NO |

84746-24-7 |

| Molecular Formula | C12H14N6 |

| Molecular weight | 242.30 |

| Inquiry Status | In Stock |

| Synonyms | 2,2′-(Piperazine-1,4-diyl)dipyrimidine |

Detailed Overview of this Impurity: Discover more about Impurity Standard & Analysis

Impurity Profiling of Buspirone Impurity G: A Scientific Perspective

Introduction

The assessment of impurities within active pharmaceutical ingredients (APIs) has become an indispensable part of modern drug development. Among these, Buspirone Impurity G represents a category of structural variants that may arise during synthesis or storage of the parent compound. Understanding its presence and behavior is essential to ensure that the therapeutic agent maintains both safety and efficacy. A systematic evaluation of impurity profiles not only meets regulatory expectations but also helps manufacturers refine synthetic processes and establish a robust quality framework. This article presents a comprehensive perspective on impurity profiling, focusing on the origins, detection, validation, purification, and characterization of Buspirone Impurity G.

Formation of Impurities During API Synthesis

Impurities in pharmaceutical compounds such as Buspirone Impurity G often emerge as an inevitable outcome of chemical synthesis. They can originate from incomplete conversions, residual reagents, or side products resulting from competing chemical reactions. Additionally, the stability of the compound under environmental influences—such as moisture, light, or oxidative conditions—can further lead to degradation-related impurities. The complexity of synthetic routes, particularly those involving multiple intermediates or catalysts, increases the likelihood of unintended chemical species. A thorough understanding of the reaction pathway is therefore fundamental for predicting and minimizing impurity formation.

Analytical Data Interpretation Techniques

Profiling of Buspirone Impurity G relies heavily on advanced analytical techniques that provide insight into both qualitative and quantitative aspects of impurities. Methods including chromatographic separations, mass spectrometry, and nuclear magnetic resonance spectroscopy are frequently employed to identify chemical structures and assess impurity distribution. Interpretation of the data involves correlating retention behaviors, fragmentation patterns, and spectral signals to differentiate the impurity from the primary API. Establishing a clear analytical fingerprint is essential for reproducibility and for monitoring product quality across different manufacturing batches.

Method Validation for Impurity Detection

For any impurity detection strategy to be reliable, analytical methods must undergo rigorous validation. When applied to Buspirone Impurity G, validation confirms that the chosen methods perform with precision, accuracy, and specificity. Parameters such as reproducibility, sensitivity, and robustness are evaluated in alignment with regulatory guidelines. The goal is to ensure that the technique consistently identifies and quantifies the impurity without interference from the parent drug or related compounds. Validation not only assures scientific reliability but also strengthens regulatory acceptance and patient safety assurance.

Purification Strategies for Reducing Impurities

Purification represents a vital step in controlling impurity levels within the final API. For Buspirone Impurity G, purification strategies may involve techniques like crystallization, solvent-based separations, or chromatographic purification, each selected based on the physicochemical properties of the impurity relative to the parent compound. The principle is to selectively remove or minimize impurities while preserving the integrity and yield of the desired substance. Developing a tailored purification approach enhances both the consistency of the product and the overall efficiency of the manufacturing process.

Isolation and Characterization of Impurities

Once identified, impurities that exceed threshold levels or remain structurally unresolved require isolation for in-depth characterization. In the case of Buspirone Impurity G, isolation may be achieved through preparative chromatographic techniques, followed by detailed structural elucidation using tools such as NMR, MS, or IR spectroscopy. This step not only reveals the molecular structure but also supports toxicological evaluation and safety assessments. Characterized impurities may then be used to generate reference standards, aiding in long-term quality control and regulatory documentation.

Conclusion

The impurity profiling of Buspirone Impurity G underscores the multidimensional nature of pharmaceutical quality assurance. From understanding the conditions that give rise to impurities, through implementing robust analytical and validation strategies, to applying efficient purification and structural characterization techniques—each step is critical in safeguarding drug quality. By integrating scientific rigor with regulatory compliance, the pharmaceutical industry ensures that the final drug product remains safe, effective, and reliable for patient use. The study of impurities like Buspirone Impurity G highlights the essential role of impurity profiling in the lifecycle management of APIs.